Mechanics

Our Mechanical Solution

Mechanical design is an essential part of many engineering projects, and covers several specific areas depending on the needs of each project. Here's an overview of what your company could offer in the way of a mechanical study:

Mechanical Design

Design of Parts and Systems

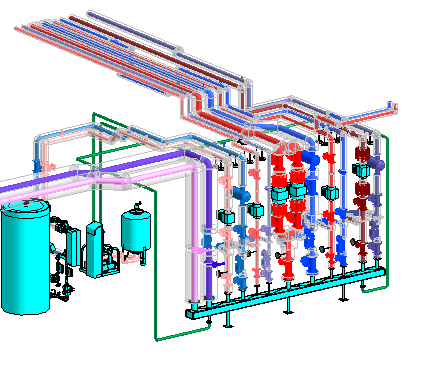

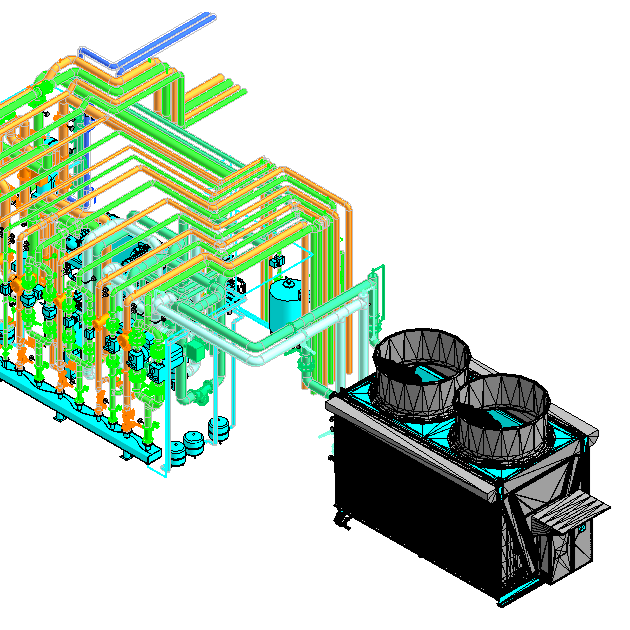

Creating models of mechanical components, such as structures, machines, motors, transmission systems, etc

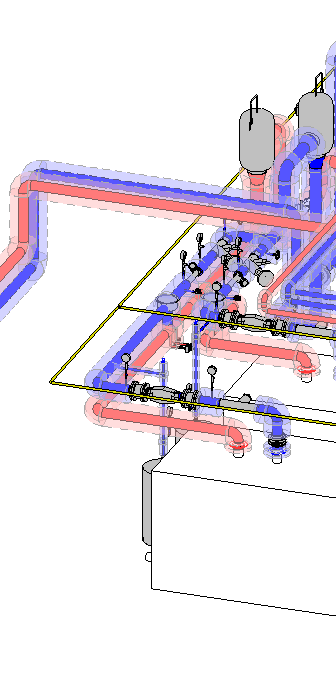

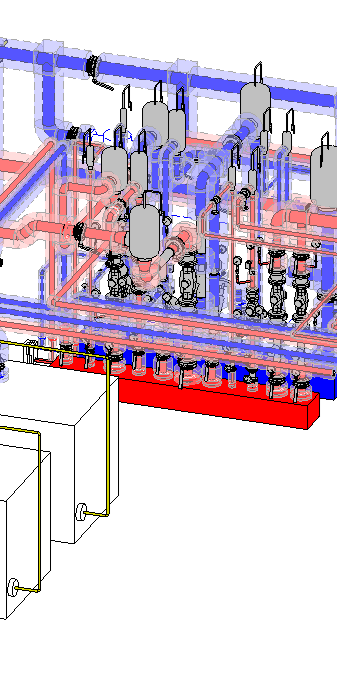

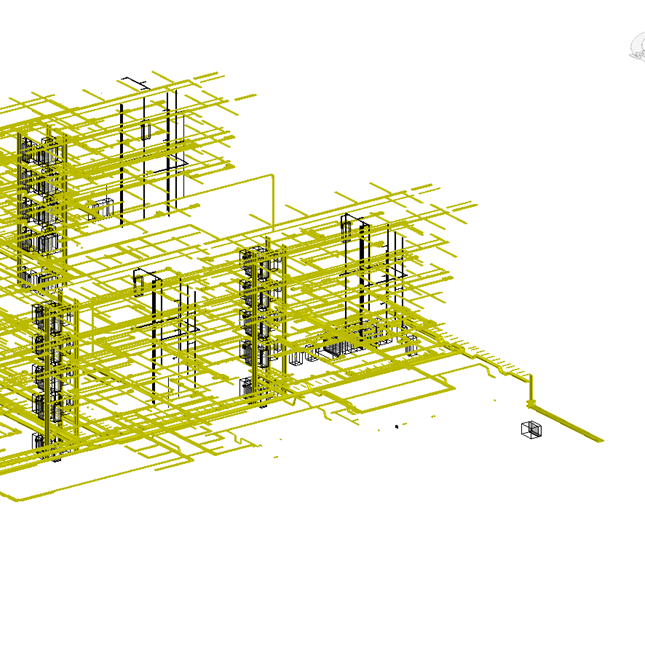

Use of CAD (Computer-Aided Design) Software

Using software like AutoCAD to model and test parts and systems in 3D before manufacturing.

Calculations and Sizing

Material Strength Calculations: Calculations to determine if the chosen materials can withstand loads and stresses without deforming or breaking.

Sizing of Components: Defining the optimal dimensions of parts to ensure maximum performance while minimizing costs.

Thermal and Dynamic Stress Analysis: Assessing the thermal effects (heating, cooling) and dynamic effects (vibrations, movements) on mechanical systems.

Reliability and Durability Analysis

Before manufacturing, it is essential to verify that the systems will function properly under real-world conditions.

Reliability Analysis

Predict the lifespan and behavior of components under various operating conditions.

Load and Deformation Simulation

Perform simulations to see how the parts react under different forces or temperatures (using simulation software).

Fatigue Testing

Study the material's resistance to repeated loading cycles to prevent long-term failures.

Prototyping and Testing

Once designs have been validated, prototypes are often created to test their performance in real-life conditions.

Prototype production: Creation of physical models of mechanical parts and systems for practical testing.

On-site testing: Performing tests on actual installations to assess system behavior under operational conditions.

Optimization of Mechanical Systems

Optimization involves improving the design to achieve higher performance while reducing costs or environmental impact.

Manufacturing cost optimization: Reduce production costs while maintaining system performance.

Ecodesign: Choose sustainable materials and manufacturing processes to minimize the ecological footprint of products.

Energy optimization: Reduce the energy consumption of mechanical equipment (for example, in ventilation systems, motors or industrial processes).

Management and Coordination

In a design office, project management is crucial to the smooth running of mechanical studies.

Planning: Organize and plan all stages of the project, from conception to completion.

Coordination with other disciplines: Work closely with teams from other disciplines (electrical, thermal, civil, etc.) to ensure seamless integration of mechanical systems into the overall project.

Monitoring quality and deadlines: Ensuring that the project meets quality requirements, delivery deadlines and projected costs.

Compliance Requirements

All mechanical projects must comply with local and international standards.

Safety regulations:

Ensuring compliance with legal safety requirements, particularly for pressurized systems, industrial equipment, etc.

Environmental standards:

Ensuring that mechanical solutions are ecologically responsible and comply with regulations on emissions, noise, etc.

Ready to bring your mechanical projects to life?

At Yafu-bim, we combine expertise, innovation and rigor to design mechanical solutions that meet your most complex needs. From design to implementation, we're with you every step of the way to guarantee the performance, reliability and durability of your systems.

Trust our team of experts to turn your mechanical challenges into concrete successes. Contact us today to discuss how we can work together to make your projects a reality.

Wir benötigen Ihre Zustimmung zum Laden der Übersetzungen

Wir nutzen einen Drittanbieter-Service, um den Inhalt der Website zu übersetzen, der möglicherweise Daten über Ihre Aktivitäten sammelt. Bitte überprüfen Sie die Details in der Datenschutzerklärung und akzeptieren Sie den Dienst, um die Übersetzungen zu sehen.